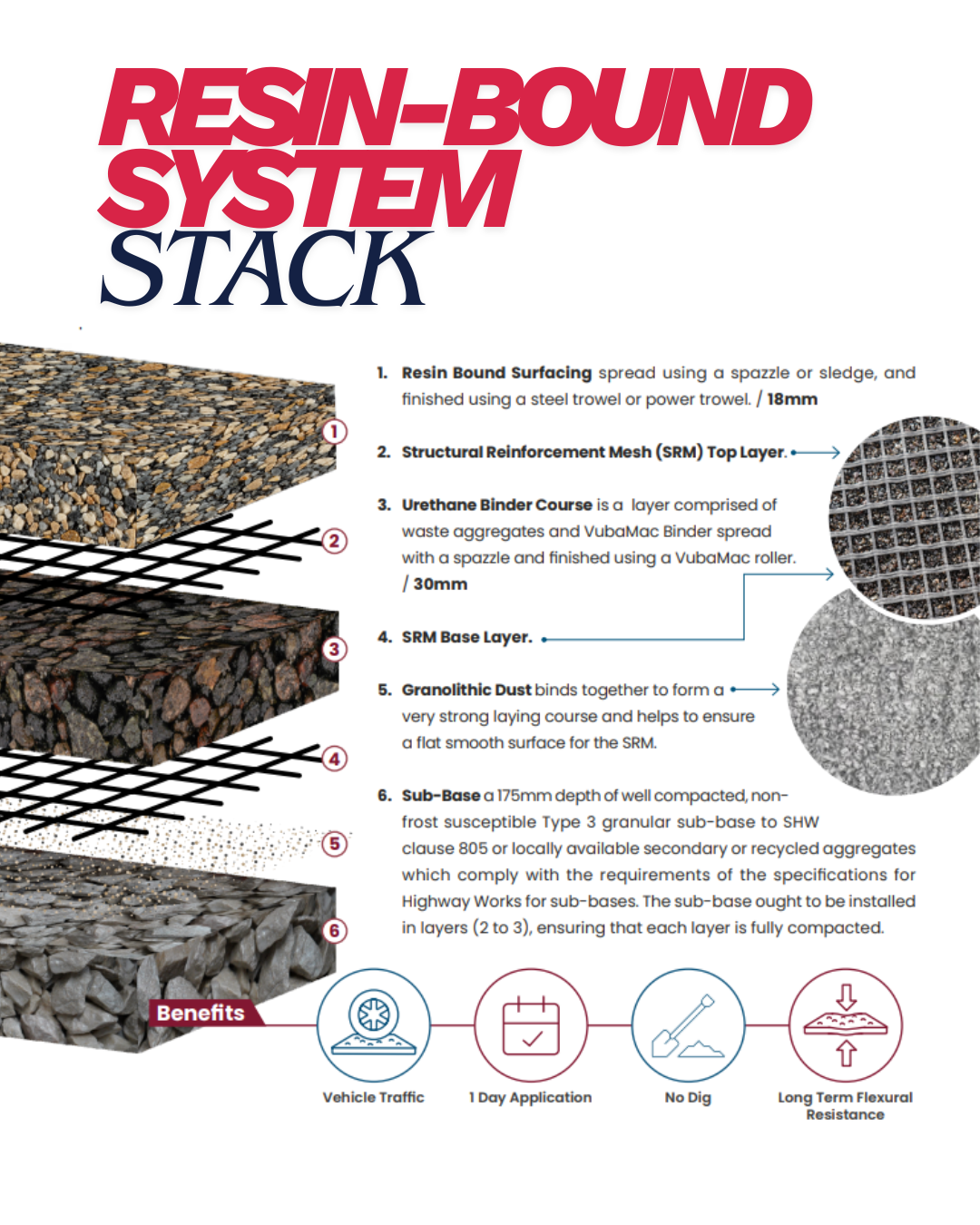

1) Consultation & Site Assessment

The resin installation process begins with a calm, thorough look at the space. A site manager notes how vehicles park, how people walk across the area, where water currently gathers and how light falls across the front or back of the property.

Usage, levels and drainage are recorded carefully so that the design suits real life, not just a brochure picture. Shared notes often include ideas from the resin versus traditional surfaces guide to help narrow the options early.