Resin Bound vs Bonded Gravel?

What’s the Difference and Which Surface Actually Lasts?

Choosing between resin bound vs bonded gravel can feel confusing at first glance. Both use decorative aggregates and resin, and both can look similar in photos. The difference is in how they’re installed, how they perform, and how they hold up over time. One is designed as a fully permeable, long-term surface. The other is a surface dressing that prioritises speed and lower upfront cost. Understanding the practical differences between resin bound and bonded gravel helps homeowners make a decision based on durability, drainage, and real-world use rather than appearance alone.

Resin Bound vs Resin Bonded Gravel: Which Is Best?

TLDR - Quick Takeaways

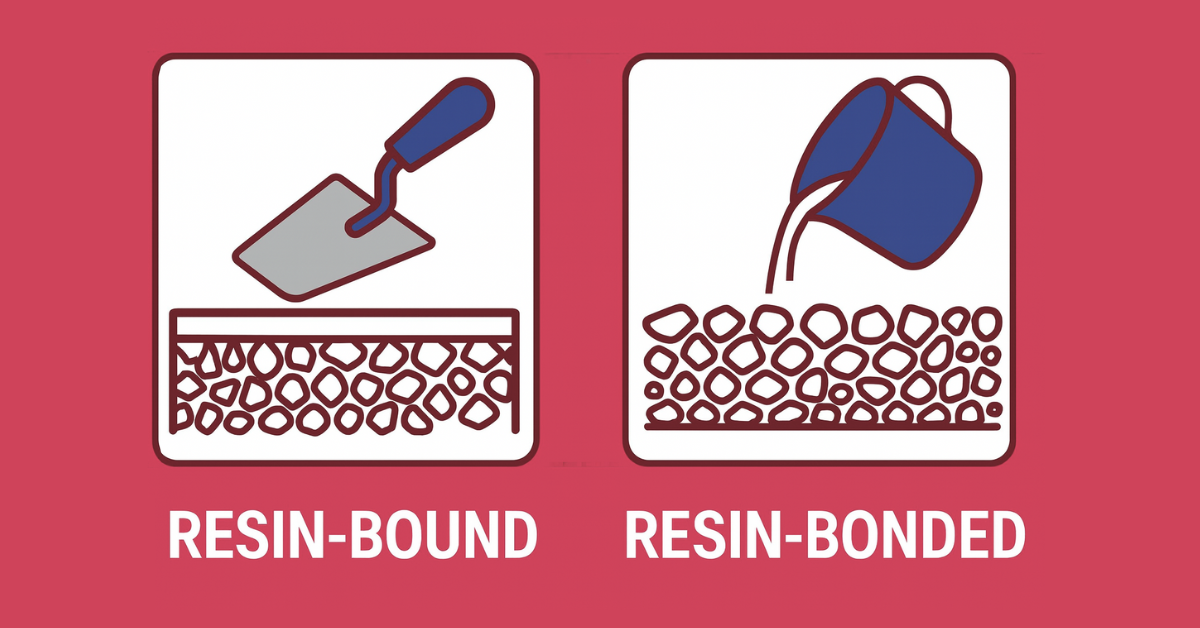

- Resin bound is a fully mixed system. Every stone is coated in resin, creating a smooth, seamless and usually permeable surface that suits driveways, patios and paths.

- Resin bonded is a scatter system. Resin is applied first, then stone is broadcast over the top, leaving a rougher, non-draining finish that behaves more like a glued gravel layer.

- For most front drives and family spaces, resin bound offers better drainage, more comfortable foot traffic and stronger long-term kerb appeal.

- Resin bonded can offer extra grip underfoot, but it isn’t the best choice for steep slopes or high rainfall because it isn’t permeable and loose stone can shed. If the area is sloped or regularly gets heavy rain, resin bound is usually the safer long-term option.

- Surface performance depends as much on the base and installation quality as on the product label, so contractor choice matters.

- Budget planning is easier with the Home Improvement Loan Calculator which shows likely monthly repayments and project cost bands.

- Typical pricing, finance options and value questions are covered in more depth in the Resin Cost & Finance FAQs.

- Before booking site visits, free guides, checklists and planning tools in the Homeowner Resources library help line everything up in the right order.

Fast Visual Overview

What Is Resin Bound?

Resin bound surfacing is created by mixing decorative stone aggregate and clear resin together in a forced action mixer. Every stone is fully coated before the blend is trowelled down onto the prepared base at a set depth. Once cured, the result is a smooth, seamless layer with tiny gaps between the stones that allow water to pass through.

A properly installed resin bound driveway or path is:

- Permeable when installed on the right sub-base, which helps with drainage and SuDS-friendly design.

- Comfortable underfoot with a tight, even texture that is kinder to tyres, pram wheels and mobility aids.

- Low maintenance because there are no loose stones to migrate into flower beds, lawns or the hallway.

- Highly decorative thanks to a wide choice of stone blends and colours that can be tailored to the property.

Because the stones are fully bound within the resin, the surface behaves more like a single continuous layer rather than loose gravel. That makes it suitable for cars, vans and regular foot traffic when installed at the correct depth and on the right base.

During installation the mixed material is trowelled by hand in small bays. A consistent depth, neat edges and smooth finish all rely on the installer’s technique. Well laid resin bound surfacing looks calm and even rather than patchy or rippled.

What Is Resin Bonded Gravel?

Resin bonded gravel is sometimes called a scatter coat or broadcast system. A layer of resin is applied to the base and loose aggregate is scattered over the wet surface. As the resin cures, the stones that make contact bond in place and any excess is brushed away.

In a resin bound vs bonded gravel comparison, the key difference is performance. Resin bonded gravel creates an attractive stone finish, but it behaves more like a sealed surface than a porous one.

- Usually non-permeable, because the resin layer underneath acts as a seal.

- More textured underfoot, with a grippier feel and more prominent stone edges.

- Stone loss can occur over time in higher-traffic areas, especially where vehicles turn.

- Lifespan depends on specification, base preparation and ongoing care.

Resin bonded gravel can be a good fit for paths, access ramps and sloped areas where extra grip is the priority and full permeability is not essential. It can also suit courtyards where the look of traditional gravel is wanted without constant raking and wheel ruts.

If drainage is a requirement, this is where the resin bound vs bonded gravel distinction matters most, resin bound systems are designed to allow water through, whereas resin bonded gravel typically is not.

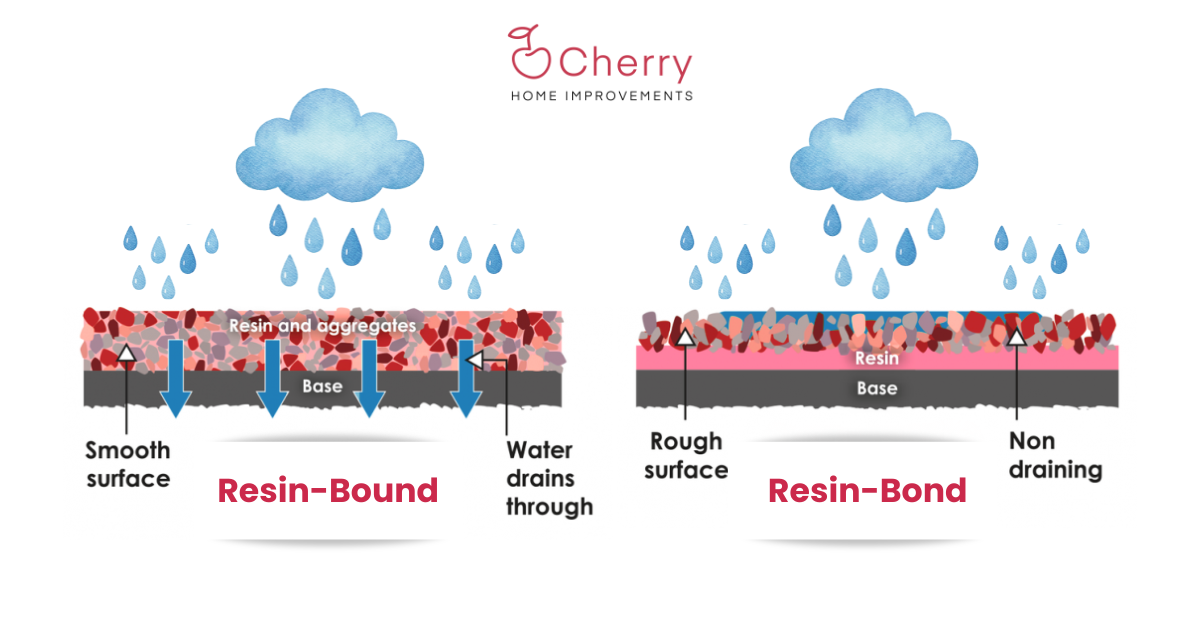

Drainage and Permeability

Drainage is one of the biggest practical differences between resin bound and resin bonded systems. Resin bound surfacing, laid on an appropriate permeable base, allows rainwater to pass through the surface and into the sub-base. This helps reduce standing water and can support a SuDS-friendly layout for drives and larger paved areas.

Resin bonded gravel behaves more like concrete, tarmac or paving on a solid bed. Water runs off rather than soaking through, so gulleys, slot drains or careful falls towards borders often need to be built into the design.

On plots where water management is already a concern, resin bound on a suitable base usually offers the more flexible long-term solution.

What Happens Inside the Surface Layer

In a resin bound blend, the binder wraps around each stone and ties the whole layer together. The small gaps that remain between aggregates let water and air move through the surface without dislodging the stone.

In a resin bonded system, the binder forms a continuous film over the base. Stone is pressed into that film, but the binder itself has no deliberate voids, which is why most resin bonded surfaces are classed as non-permeable.

This structural difference explains why resin bound is typically chosen for full driveways and heavily used areas, while resin bonded is reserved for more decorative or grip-critical zones.

Some products described as pour-on gravel binders sit somewhere between these two systems. They can stabilise loose stone on paths or seating areas, although they do not behave in the same way as a fully mixed resin bound surface.

Resin Bound vs Resin Bonded - At a Glance

With the structure and drainage differences in mind, it helps to see the key points side by side. The comparison below highlights how each surface behaves in day to day use around a typical UK home.

Where Resin Bound Usually Works Best

For many residential properties in the UK, resin bound surfacing is the preferred choice for:

- Driveways and entrances where a smart, even finish matters as much as strength.

- Patios and pathways that need to look attractive without loose stones travelling into the house.

- Accessible routes for wheelchairs, prams and mobility scooters.

- Pool surrounds and garden seating areas where bare feet and outdoor furniture need a comfortable surface.

The combination of permeability, smooth texture and wide colour choice gives impressive kerb appeal with practical day to day benefits. For inspiration on how resin bound can be used around real properties, the gallery on the Hampshire Resin Method page is a helpful place to start.

When Resin Bonded Gravel Can Be Useful

Resin bonded gravel still has a place in certain situations, particularly where additional surface grip is the main priority and full permeability is less important. Examples include:

- Heritage-style courtyards and lightly used paths where the look of loose stone is wanted, and drainage is already handled.

- Access ramps where tyre grip is critical.

- Courtyards where the look of loose stone is desired without constant raking.

In these cases, a carefully planned drainage design and a clear discussion about long-term maintenance help set realistic expectations.

Installation Quality Matters as Much as the Product Name

Whether the final choice is resin bound or resin bonded, the quality of the base and installation is just as important as the system label. Key points to check with any contractor include:

- Base preparation and whether the existing surface needs to be removed, repaired or fully replaced.

- Specified depth of the resin layer, especially for vehicle areas and turning circles.

- Resin type and whether it is UV stable to resist discolouration over time.

- Guarantees on both materials and workmanship, written in clear language.

- Experience with similar homes and ground conditions in the local area.

Regular sweeping, occasional power washing on a gentle setting and prompt removal of moss or algae will help any resin surface stay at its best for longer, regardless of whether it is resin bound or resin bonded.

Next Steps - Plan a Resin Project with Confidence

A resin driveway, patio or pathway is a significant investment, so it helps to have the numbers, layout and priorities clear before inviting contractors round. Three resources are particularly useful at the planning stage.

- Use the Home Improvement Loan Calculator to explore project cost bands, approximate monthly repayments and how different loan terms might sit alongside the household budget.

- Read the Resin Cost & Finance FAQs for straight answers to common questions on pricing, finance options and long-term value.

- Download free guides and checklists from the Homeowner Resources library to keep quotes, design decisions and timeframes organised from the very first enquiry.

After a brief visit to those pages, the choice between resin bound and resin bonded tends to feel far clearer, and any future site survey can focus on accurate measurements, ground conditions and design detail rather than basic definitions.

Resin Bound Vs Bonded Gravel – FAQs

Which surface looks better long term: resin bound vs bonded gravel?

When comparing resin bound vs bonded gravel, long-term appearance is a major deciding factor. Resin-bound surfaces retain a smooth, consistent finish because the aggregate is fully encapsulated within the resin. Bonded gravel can look good initially, but over time loose stones, wear patterns, and patchiness can affect the overall look, especially in high-use areas.

If you’d like to compare resin surfaces before using the visualiser, this guide is a helpful starting point.

For external standards on outdoor design tools, the Landscape Institute publishes guidance on visual accuracy in exterior design.

Does resin bound vs bonded gravel affect maintenance requirements?

Yes, maintenance is one of the practical differences between resin bound vs bonded gravel. Resin bound surfaces are easier to maintain as there are no loose stones and fewer places for weeds to establish. Bonded gravel may require more frequent sweeping and upkeep as aggregate can dislodge and collect in surrounding areas.

You can explore real resin colours here before choosing blends for your ResinVision™ Studio preview.

And for downloadable photo guides and finish resources, visit The Homeowner Resource page…

If you want an external reference for image-based design tools, CIRIA’s SuDS guidance includes helpful notes on surface reflectance and outdoor material choices.

Is resin bound vs bonded gravel suitable for sloped driveways?

Slope performance is another key consideration when choosing between resin bound vs bonded gravel. Resin-bound systems are generally more suitable for sloped areas because the bound aggregate creates a stable, unified surface. Bonded gravel, by contrast, can be more prone to stone movement on gradients, which may affect both safety and appearance.

If you’re unsure, you can find more detailed resin driveway FAQs here…

How do installation standards differ for resin bound vs bonded gravel?

Installation quality matters greatly in resin bound vs bonded gravel comparisons. Resin-bound surfacing relies on precise mixing, timing, and base preparation to achieve correct permeability and strength. Bonded gravel installations are often quicker, but the surface performance depends heavily on resin coverage and curing conditions, making professional standards essential either way.

If you are happy to take the next step, you can order sample packs here.

After that, a full design assessment provides a detailed breakdown of installation requirements, base-build considerations, and pricing.

How do I decide between resin bound vs bonded gravel for my property?

Deciding between resin bound vs bonded gravel comes down to how the surface will be used, how long you expect it to last, and how much ongoing maintenance you’re comfortable with.

While both systems use decorative aggregates and resin, they are designed for very different outcomes. A resin bound driveway system is a fully mixed installation where aggregate and resin are combined before application, creating a smooth, porous, and structurally consistent surface. Bonded gravel, by contrast, is applied by scattering loose aggregate onto a resin-coated base, which can result in stone movement over time.

When comparing resin bound vs bonded gravel, usage is a critical factor. Areas such as residential driveways, parking spaces, and frequently used paths generally perform better with resin bound surfacing because it provides long-term stability under load. Bonded gravel is more often used in decorative settings or low-traffic areas, where appearance is prioritised over durability.

Drainage also plays a role in resin bound vs bonded gravel decisions, as resin bound systems are designed to be permeable and SuDS-compliant when installed correctly, unlike bonded surfaces.

Maintenance expectations are another key consideration in resin bound vs bonded gravel comparisons. Resin bound surfaces typically require less routine upkeep, with fewer issues related to weed growth or surface breakdown.

Homeowners exploring long-term performance often find additional guidance helpful, which is why many refer to expert answers and FAQs when weighing up surface options.

Ultimately, choosing between resin bound vs bonded gravel is about matching the surface to the property’s practical requirements rather than selecting purely on appearance or initial cost.

Your story

Got something to add? Share what you know, what you’ve learned and any advice you’d give other readers. The useful bits, the mistakes, the “wish I’d known that sooner” moments.

If you’re feeling creative, write it like a mini story or blog post (up to roughly 800 words). If it’s genuinely helpful or a great read, we may publish it in our collection and credit your name.