When the driveway finally matches the house

Most homes reach a point where the driveway lets the whole place down. The brickwork, planting and windows are doing their best, but the concrete or asphalt at the front is cracked, stained and patched.

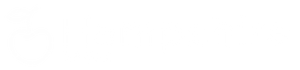

Vuba resin changes that.

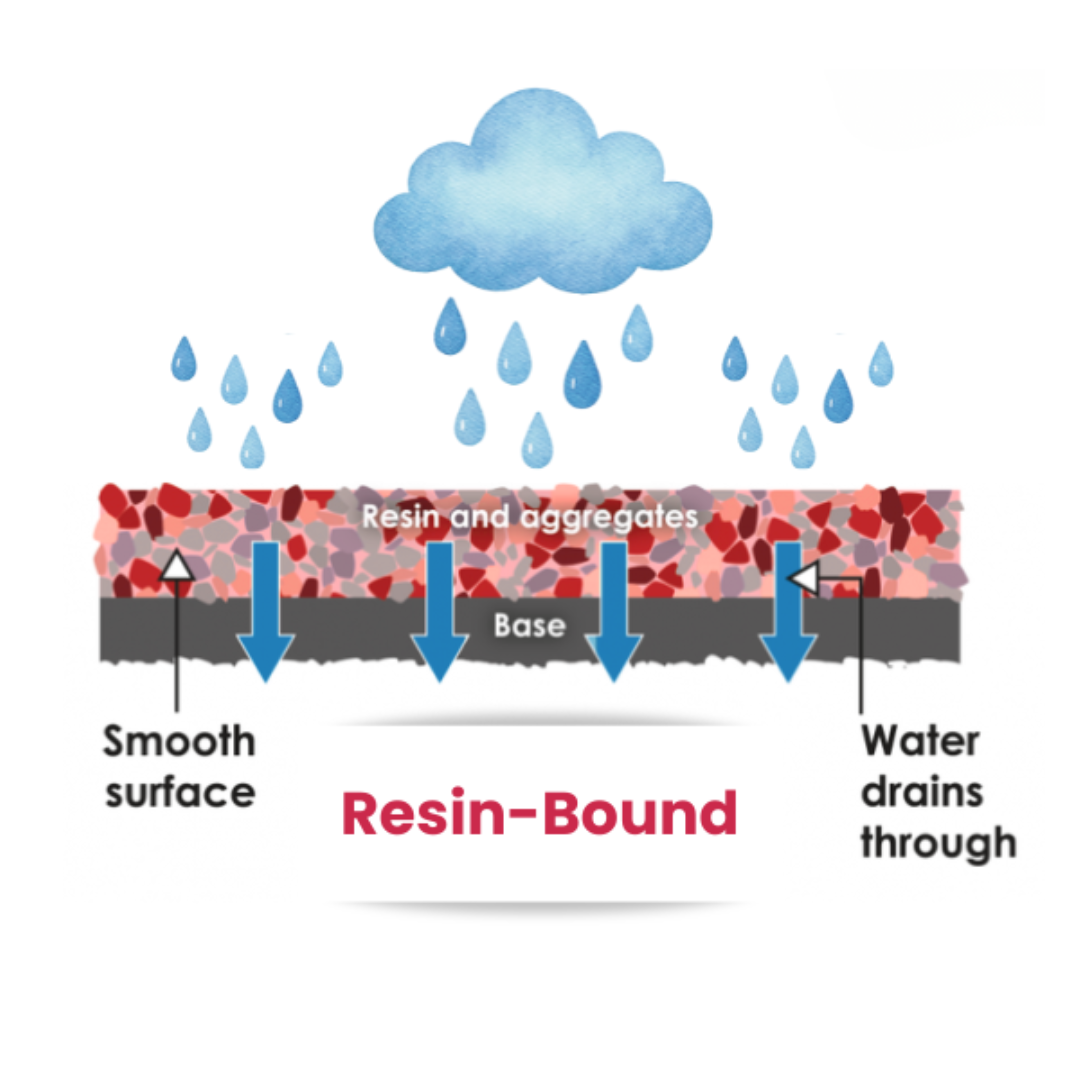

A Vuba system turns the entrance into part of the home, not an afterthought, with a surface that feels firm under the wheels, smooth under bare feet and quietly impressive every time the car pulls up on the drive.

“Quality is never an accident; it is always the result of intelligent effort.” - John Ruskin

Ready to explore what that could look like at your property?