Resin installation quality assurance exists to give that confidence by showing exactly how durability, strength and long-term performance are achieved. When each stage of the process is clear, you know what to expect, how the surface will behave over time and why it stands up so well to daily life. Go through the checks, standards, and techniques that help your driveway, patio, or outdoor space feel secure, consistent, and beautifully finished for years to come.

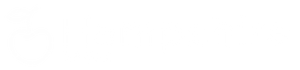

A resin surface only performs beautifully when the hidden layers are built correctly. Resin installation quality assurance gives you faith that the surface under your feet will remain strong, stable, and visually consistent over time. Most of the life span comes from what happens long before the final hand-trowelled finish. A high-performing installation means:

a stable sub-base that won’t shift under pressure

controlled moisture levels to prevent future cracking

drainage designed to keep the surface dry and safe

mixing ratios that keep the resin strong and elastic

hand-finishing that avoids weak spots around edges and borders

As a discerning homeowner, you want to see these Resin Installation Quality Assurance standards laid out step by step. You can see those steps below…